| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | WITGAIN PCB |

| Model Number : | PCB000385 |

| Certification : | UL |

| Price : | negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100kpcs/Moth |

| Delivery Time : | 20 days |

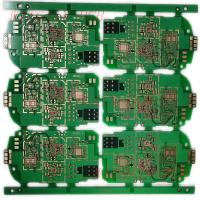

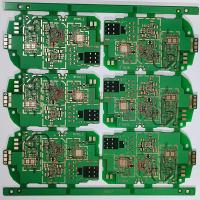

10 Layer Printed Circuit Board ISO 14001 Qualified Used In Medical Equipment

Main Features:

1 10 Layer customized printed circuit board manufacturered based on customer's gerber files.

2 Used in Motor areas.

3 Material is FR4 S1000-2 TG170.

4 The finished board thickness is 2.0MM.

5 The finished copper thickness is 35UM.

6 Surface treatment is ENIG 2U'.

7 Drilling: L1-L5 0.2MM, L6-L10 0.2MM, L1-L10 0.2MM

8 Lead time is around 20 working days.

Material Data Sheet:

| S1000-2 | |||||

| Items | Method | Condition | Unit | Typical Value | |

| Tg | IPC-TM-650 2.4.25 | DSC | ℃ | 180 | |

| IPC-TM-650 2.4.24.4 | DMA | ℃ | 185 | ||

| Td | IPC-TM-650 2.4.24.6 | 5% wt. loss | ℃ | 345 | |

| CTE (Z-axis) | IPC-TM-650 2.4.24 | Before Tg | ppm/℃ | 45 | |

| After Tg | ppm/℃ | 220 | |||

| 50-260℃ | % | 2.8 | |||

| T260 | IPC-TM-650 2.4.24.1 | TMA | min | 60 | |

| T288 | IPC-TM-650 2.4.24.1 | TMA | min | 20 | |

| T300 | IPC-TM-650 2.4.24.1 | TMA | min | 5 | |

| Thermal Stress | IPC-TM-650 2.4.13.1 | 288℃, solder dip | -- | 100S No Delamination | |

| Volume Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ.cm | 2.2 x 108 | |

| E-24/125 | MΩ.cm | 4.5 x 106 | |||

| Surface Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ | 7.9 x 107 | |

| E-24/125 | MΩ | 1.7 x 106 | |||

| Arc Resistance | IPC-TM-650 2.5.1 | D-48/50+D-4/23 | s | 100 | |

| Dielectric Breakdown | IPC-TM-650 2.5.6 | D-48/50+D-4/23 | kV | 63 | |

| Dissipation Constant (Dk) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 4.8 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Dissipation Factor (Df) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 0.013 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Peel Strength (1Oz HTE copper foil) | IPC-TM-650 2.4.8 | A | N/mm | — | |

| After thermal Stress 288℃,10s | N/mm | 1.38 | |||

| 125℃ | N/mm | 1.07 | |||

| Flexural Strength | LW | IPC-TM-650 2.4.4 | A | MPa | 562 |

| CW | IPC-TM-650 2.4.4 | A | MPa | 518 | |

| Water Absorption | IPC-TM-650 2.6.2.1 | E-1/105+D-24/23 | % | 0.1 | |

| CTI | IEC60112 | A | Rating | PLC 3 | |

| Flammability | UL94 | C-48/23/50 | Rating | V-0 | |

| E-24/125 | Rating | V-0 | |||

FQA:

Q1: What is a PCB Test Coupon?

A1: During the PCB Manufacturing process, it is important to evaluate the quality of the boards being fabricated. A good way to do this is to fabricate a few extra boards called PCB Test Coupons which can be tested to evaluate the performance of the boards. PCB Test Coupons are designed to have the same spec (trace width, copper weight, via structure, etc.) as the original PCB board and are tested to identify manufacturing defects, material defects or other related defects.

During the PCB Fabrication process multiple PCBs are fabricated on a large board called a panel. The PCB Test Coupon is usually not a part of the core PCB panel, is built in section surrounding the PCBs. They are designed to represent actual board conditions for plating, etching and lamination. It's common to fabricate one coupon at each end of a board panel to verify performance across the entire panel. Any defect identified in the PCB Test Coupon would mean that other boards on the same panel would have the same issues.

Advantages of using PCB Test Coupon:

|