| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | WITGAIN PCB |

| Model Number : | PCB000386 |

| Certification : | UL |

| Price : | negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100kpcs/Moth |

| Delivery Time : | 20 days |

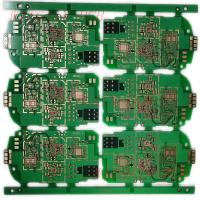

10 Layer Printed Circuit Board ISO 14001 Qualified Used In Medical Equipment

Material Data Sheet:

| S1000-2 | |||||

| Items | Method | Condition | Unit | Typical Value | |

| Tg | IPC-TM-650 2.4.25 | DSC | ℃ | 180 | |

| IPC-TM-650 2.4.24.4 | DMA | ℃ | 185 | ||

| Td | IPC-TM-650 2.4.24.6 | 5% wt. loss | ℃ | 345 | |

| CTE (Z-axis) | IPC-TM-650 2.4.24 | Before Tg | ppm/℃ | 45 | |

| After Tg | ppm/℃ | 220 | |||

| 50-260℃ | % | 2.8 | |||

| T260 | IPC-TM-650 2.4.24.1 | TMA | min | 60 | |

| T288 | IPC-TM-650 2.4.24.1 | TMA | min | 20 | |

| T300 | IPC-TM-650 2.4.24.1 | TMA | min | 5 | |

| Thermal Stress | IPC-TM-650 2.4.13.1 | 288℃, solder dip | -- | 100S No Delamination | |

| Volume Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ.cm | 2.2 x 108 | |

| E-24/125 | MΩ.cm | 4.5 x 106 | |||

| Surface Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ | 7.9 x 107 | |

| E-24/125 | MΩ | 1.7 x 106 | |||

| Arc Resistance | IPC-TM-650 2.5.1 | D-48/50+D-4/23 | s | 100 | |

| Dielectric Breakdown | IPC-TM-650 2.5.6 | D-48/50+D-4/23 | kV | 63 | |

| Dissipation Constant (Dk) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 4.8 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Dissipation Factor (Df) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 0.013 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Peel Strength (1Oz HTE copper foil) | IPC-TM-650 2.4.8 | A | N/mm | — | |

| After thermal Stress 288℃,10s | N/mm | 1.38 | |||

| 125℃ | N/mm | 1.07 | |||

| Flexural Strength | LW | IPC-TM-650 2.4.4 | A | MPa | 562 |

| CW | IPC-TM-650 2.4.4 | A | MPa | 518 | |

| Water Absorption | IPC-TM-650 2.6.2.1 | E-1/105+D-24/23 | % | 0.1 | |

| CTI | IEC60112 | A | Rating | PLC 3 | |

| Flammability | UL94 | C-48/23/50 | Rating | V-0 | |

| E-24/125 | Rating | V-0 | |||

FQA:

Q1: What is Halogen-Free Solder Paste?

A1: Halogen-Free Solder Paste as the name suggests is a solder paste that does not contain Halogen. Fundamentally, halogens in solder paste refer to chlorine and bromine. Chlorine, is found in circuit boards, and is primarily in the form of residual materials left over from production of non-brominated epoxy resins used in board assembly. Bromine in electronics is usually added to organic materials such as a fire retardant known as brominated flame retardants (BFRs). In solder pastes bromide also play a significant role as activators. Activators are the chemicals that are added to solder fluxes to remove oxides from metal surfaces, and so allow them to join together to form a strong metallurgical bond.

Over last few years the electronics industry has been making a move to become "halogen-free" as this is more environmentally friendly. According to the JPCA-ES-01–2003, IEC 614249–2–21 and IPC 4101B standards set by industry bodies the limit for assembly halogen content is 900 ppm for, chlorine and bromine. The IEC and IPC standard bodies have set the limit for the total, combined amount of chlorine and bromine to be less than 1500 ppm.

Halogens considerably influence the wetting properties of solder paste. Halogens in solder pastes enable solder and solder pad deoxidation, which in turn boost the wetting properties of the solder paste thus improving its melting properties. Hence, they have a positive effect on the stencil life, thermal stability, the reflow process-window, as well as durability. The abandonment of halogens has a direct effect on the soldering process and other subsequent processes such as assembly cleaning. There can always be chances of poorly wetted solder joints while using halogen-free solder pastes. Also, the elimination of halogens as activators can result in head-in-pillow joints due to poor/inconsistent melting behaviour.

So, despite being an essential part of PCB world, why are halogens of concern?

There are both known and suspected risks associated with halogens in electronics. Since various halogens contained in solder pastes, are regarded as harmful to health and the environment, REACH and RoHS have banned the use of halogens. The main concern here is with the disposal of products containing halogens, particularly through incineration as a recovery method. Limits for halogens or halides are set by a number of industrial standards.

|