| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | WITGAIN PCB |

| Model Number : | GFPCB0003 |

| Certification : | UL |

| Price : | negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100k pcs/month |

| Delivery Time : | 20 days |

Gold Finger PCB 4 Layer Printed Circuit Board 1.6 MM Thickness

1 4 Layer printed circuit board with gold fingers.

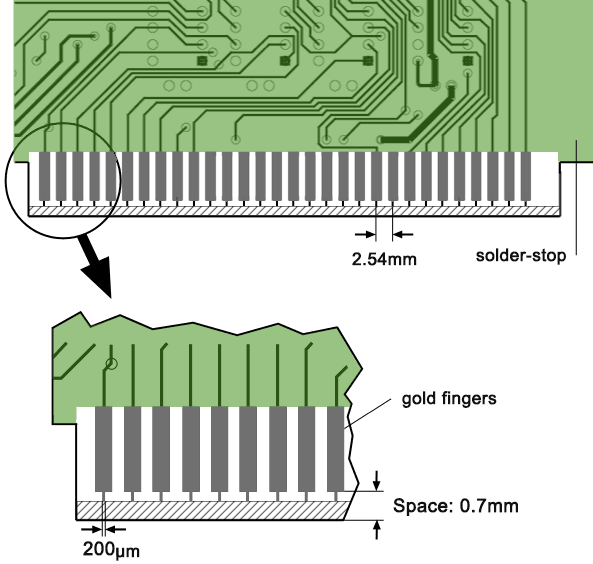

2 Gold thickness is 30U' on gold fingers.

3 FR4 sustrate material, tg170 degree.

4 Gold plating on gold fingers, for balance pads, we do immersion

gold treatment.

5 1OZ finished cooper thickness on each layer.

6 Min line space and width is 5/5mil.

7 Drawing size is 270mm*185mm/1pcs.

8 ROHS, MSDS, SGS, UL, ISO9001&ISO14001 Certificated.

1 Consumer electronic products: SSD, TWS earphones,

headsets,computer devices, portable power supplies, bluetooth

modules, gps modules, wifi modules, smart keys for cars,

intelligent locks, floor mopping robots, zigbee, etc.

2 Industrial control:main boards in machines, industrial robots,

servo motors etc.

3 Automotive: BMS main boards, automotive radar etc.

4 Power supplies: UPS, industrial power supply, frequency power

supply.

5 Medical: medical equipment, medical equipment power supply.

6 Communication products: 5G base station, routers, satellites,

antennas.

Q1: What are PCB Gold Fingers?

A1:

Gold Fingers are the gold plated narrow connectors found on the

edge of printed circuit boards to enable connections between

multiple boards. They are made from flesh gold, the hardest form of

gold available and work for a long time with superior conductivity.

The thickness of gold fingers usually ranges from 3 to 50 microns.

Gold is chosen for these fingers as it has the highest corrosion

resistance and electrical conductivity after Copper and Silver.

Sometimes, Gold is combined with Cobalt and Nickel to increase the

resistance of the fingers for wear and tear. PCBs are

connected/disconnected from each other multiple times. So these

connection points (fingers) need to be able to handle some wear and

tear.

What is PCB Gold Finger Beveling?

The PCB Gold Fingers plating process starts after the solder mask

deposition and before the surface finish. It includes the following

steps:

Design Specifications for PCB Gold Fingers:

PCBs with Non-uniform Gold Fingers:

For some PCBs, the gold fingers are intended to be shorter than

others. The most relevant example of such PCB is the one used for

memory card readers, where the device linked with long fingers must

be powered first to those connected with the shorter fingers.

PCBs with Segmented Gold Fingers

Segmented gold fingers vary in length and some of them are also

disjoined within the same fingers of the same PCB. Such PCBs are

suitable for water-resistant and rugged electronics.

Quality Measures for PCB Gold Fingers:

The Association Connecting Electronics Industries (IPC) has

prescribed some standards for the production of PCB Gold Fingers.

The IPC standards are summarized as follows:

|