| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | WITGAIN PCB |

| Model Number : | 10LayerPCB0032 |

| Certification : | UL |

| Price : | negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100kpcs/Moth |

| Delivery Time : | 20 days |

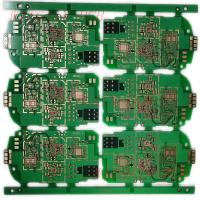

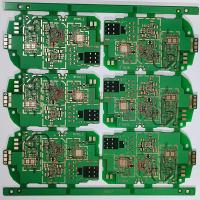

10 Layer Printed Circuit Board IATF 16949 Motor PCB Assembly

Main Features:

1 10 Layer customized printed circuit board manufacturered based on customer's gerber files.

2 Used in Motor areas.

3 Material is FR4 S1000-2 TG170.

4 The finished board thickness is 2.0MM.

5 The finished copper thickness is 35UM.

6 Surface treatment is ENIG 2U'.

7 Acceptance Standards is IATF 16949.

8 Lead time is around 20 working days.

Material Data Sheet:

| S1000-2 | |||||

| Items | Method | Condition | Unit | Typical Value | |

| Tg | IPC-TM-650 2.4.25 | DSC | ℃ | 180 | |

| IPC-TM-650 2.4.24.4 | DMA | ℃ | 185 | ||

| Td | IPC-TM-650 2.4.24.6 | 5% wt. loss | ℃ | 345 | |

| CTE (Z-axis) | IPC-TM-650 2.4.24 | Before Tg | ppm/℃ | 45 | |

| After Tg | ppm/℃ | 220 | |||

| 50-260℃ | % | 2.8 | |||

| T260 | IPC-TM-650 2.4.24.1 | TMA | min | 60 | |

| T288 | IPC-TM-650 2.4.24.1 | TMA | min | 20 | |

| T300 | IPC-TM-650 2.4.24.1 | TMA | min | 5 | |

| Thermal Stress | IPC-TM-650 2.4.13.1 | 288℃, solder dip | -- | 100S No Delamination | |

| Volume Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ.cm | 2.2 x 108 | |

| E-24/125 | MΩ.cm | 4.5 x 106 | |||

| Surface Resistivity | IPC-TM-650 2.5.17.1 | After moisture resistance | MΩ | 7.9 x 107 | |

| E-24/125 | MΩ | 1.7 x 106 | |||

| Arc Resistance | IPC-TM-650 2.5.1 | D-48/50+D-4/23 | s | 100 | |

| Dielectric Breakdown | IPC-TM-650 2.5.6 | D-48/50+D-4/23 | kV | 63 | |

| Dissipation Constant (Dk) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 4.8 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Dissipation Factor (Df) | IPC-TM-650 2.5.5.9 | 1MHz | -- | 0.013 | |

| IEC 61189-2-721 | 10GHz | -- | — | ||

| Peel Strength (1Oz HTE copper foil) | IPC-TM-650 2.4.8 | A | N/mm | — | |

| After thermal Stress 288℃,10s | N/mm | 1.38 | |||

| 125℃ | N/mm | 1.07 | |||

| Flexural Strength | LW | IPC-TM-650 2.4.4 | A | MPa | 562 |

| CW | IPC-TM-650 2.4.4 | A | MPa | 518 | |

| Water Absorption | IPC-TM-650 2.6.2.1 | E-1/105+D-24/23 | % | 0.1 | |

| CTI | IEC60112 | A | Rating | PLC 3 | |

| Flammability | UL94 | C-48/23/50 | Rating | V-0 | |

| E-24/125 | Rating | V-0 | |||

FQA:

Q1: What is a microvia?

A1: A Microvia is basically a very small via. Most PCBs now days are multi-layer boards. Vias are used to make connections between each layer of the printed circuit board. Microvias, as the name suggests have a smaller diameter and thus take up less board real estate and leave more space for routing. They also have a lower parasitic capacitance which is important for high-speed circuits. However, the manufacturing process tends to become more complex and more expensive compared to regular vias i.e Through Hole vias or Blind/burried vias.

Most PCB companies classify vias with a diameter less than 150 microns to be microvias. These vias lower the possibility of any type of manufacturing defect since they are drilled using lasers which mitigates the chances of any residue left after the process. Because of their small size and ability to connect one layer to the next they enable denser printed circuit boards with more complex designs. Most HDI printed circuit boards use microvias.

Microvias are used to connect one layer of the board to its adjacent layer and have a very small diameter in comparison to the mechanically drilled vias such as PTH (Plated Through Hole).

Microvias are of two types, Stacked and Staggered.

|