| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | WITGAIN PCB |

| Model Number : | CeramicPCB0005 |

| Certification : | UL |

| Price : | negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100k pcs/month |

| Delivery Time : | 20 days |

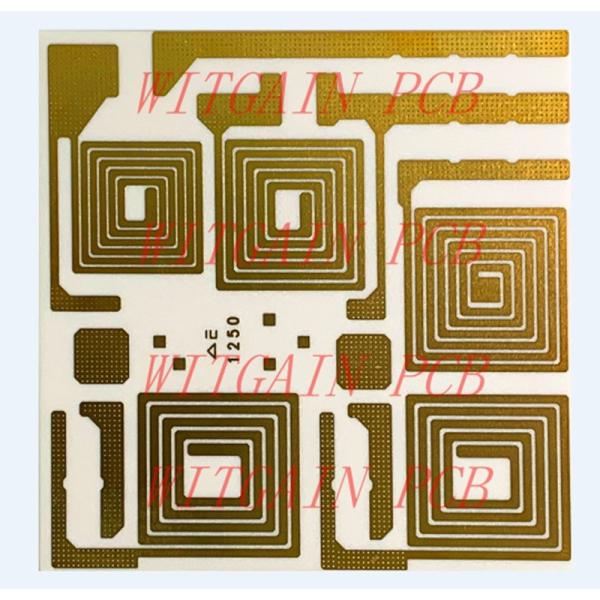

AL2O3 Ceramic PCB Board Thickness 2.3MM 3/3OZ Copper

Main Features:

1 Part NO: CeramicPCB0005

2 Layer Count: 2 Layer PCB

3 Material Kind: AL203 Ceramic

4 Finished Board Thickness: 2.3MM

5 Copper Thickness: 3/3OZ

6 PCB Size: 120MM*100MM

7 Application Area: RF Power Supply

Our Product Categories:

| Our Product Categories | ||

| Material Kinds | Layer Counts | Treatments |

| FR4 | Single Layer | HASL Lead Free |

| CEM-1 | 2 Layer/Double Layer | OSP |

| CEM-3 | 4 Layer | Immersion Gold/ENIG |

| Aluminum Substrate | 6 Layer | Hard Gold Plating |

| Iron Substrate | 8 Layer | Immersion Silver |

| PTFE | 10 Layer | Immersion Tin |

| PI Polymide | 12 Layer | Gold fingers |

| AL2O3 Ceramic Substrate | 14 Layer | Heavy copper up to 8OZ |

| Rogers, Isola high frequency materials | 16 Layer | Half plating holes |

| Halogen free | 18 Layer | HDI Laser drilling |

| Copper based | 20 Layer | Selective immersion gold |

| 22 Layer | immersion gold +OSP | |

| 24 Layer | Resin filled in vias | |

FAQ:

Q1:What are Copper Clad Laminates?

A1: A copper clad laminate is a laminate that has copper foil as

its conducting layer. Laminates form the core of a PCB. It consists

of layers of metal foil and prepreg (resin + reinforcement

material) laminated together with heat and pressure. A laminate

used for Printed Circuit Boards can have many different types of

metal foil as its conducting layer. These include copper, aluminum,

uranium, gold, palladium, carbon fiber, graphite etc. However,

copper is used the most due to its excellent electrical

characteristics and low cost.

Copper Clad Laminates are classified based on the copper weight, type of resin used, Reinforcement type, glass transition temperature, and various thermal and electrical properties.

The copper foil which is used as the conducting layer of the laminate is available in different specifications as laid out in IPC-4101. This standard also specifies the reinforcement type, the resin system the glass transition temperature range and flammability requirements for making quality copper clad laminate.

Copper Weight: Copper Weight or Copper Thickness in a Printed Circuit Board represents the thickness of 1 ounce of copper rolled out over an area of 1 square foot. It determines the current carrying capacity of a PCB. This is an important parameter that needs to be specified when selecting a copper clad laminate.

Resin: The type of resin used determines the mechanical properties related to stress and strain bearing capacity of the laminate and the thermal characteristics like the rate of expansion and curing properties, which again determine its rate of cross linking among molecular chains which determine its decomposition and glass transition temperature.

Phenolic Epoxy Polyester

PTFE Polyamide/Epoxy Epoxy/Multi Functional Epoxy

Bismaleimide Triazine(BT) Polyamide Polyimide Cyanate Ester

Cyanate Ester Epoxy/Phenolic Flame Resistant

Reinforcement: The choice of reinforcement used while manufacturing

the laminate determines its tooling and drilling characteristics.

Cotton and cellulose based laminates do not need to be drilled and

can be punched to make a hole in it. Laminates made from a fiber of

any kind like, glass, mat glass and quartz require special drilling

practices, like closely monitoring the rate of wear of drill bit,

the pressure applied to the drill bit and the spindle speed. This

is because the thickness and granularity of the glass fibers, the

thickness of the copper foil have a huge impact on the number of

times a drill bit can be used, which ultimately has an impact on

the final cost of making the laminate.

Cotton Paper

Woven Glass

Mat Glass

Cotton Paper/Woven Glass

Woven Glass/Mat Glass

Mat Glass/ Glass Veil

Woven Aramid

Woven Quartz Fiber

Woven E-Glass Surface/Cellulose Paper Core

A copper clad laminate is basically a combination of these layers.

The combination determines various mechanical, physical, thermal

and electrical properties of the laminate. The properties include

the Glass Transition Temperature, the coefficient of thermal

expansion. Electrical properties of the board include Dielectric

Constant, loss tangent, insulation Resistance, surface resistivity

and various other parameters.

|